Electric Utility

Our fiberglass Secondary Containment System and Utility Covers System are ideal for use in electrical substation applications and both are low in conductivity, lightweight and easy to install.

Secondary Containment Systems

The COMPOSOLITE® Secondary Containment System is ideal for use in any application requiring secure containment of liquid or solid materials. The system was initially developed in conjunction with American Electric Power and has been widely accepted by many utilities. Current installations number 500-plus.

The lightweight, high-strength pultruded fiberglass Containment System is much easier and more cost effective to install than poured-in-place concrete or earthen containment alternatives. The system also can easily be installed in confined or remote areas and may be easily removed if necessary.

Each COMPOSOLITE® Secondary Containment System is designed for your specific application. Systems are prefabricated by Strongwell and shipped in kit form for field assembly.

Each COMPOSOLITE® Secondary Containment System is designed for your specific application. Systems are prefabricated by Strongwell and shipped in kit form for field assembly.

An optional liner can be added for further protection against leaks in applications involving liquid containment.

Features and Benefits:

- Strong

- Lightweight

- Easy to Install

- Reduced Installation Costs

- Corrosion Resistant

- Low Maintenance

- Low Conductivity

- Easy to Transport

Typical applications include oil containment for electric substation transformers, secondary containment for chemical storage areas and containment walls around construction sites.

Kit Contents

Each containment system is shipped with the following materials:

- COMPOSOLITE® panels - maximum length 24'; weight approximately 7.5 lbs/ft.

- Square tubes for post with predrilled holes

- Corner angles with predrilled holes

- 316 stainless steel bolts

- Cap channel with nylon rivets - furnished in 20' lengths for field cutting

- Drill bits for bolts and rivets

- Tubes of Pliogrip® adhesive

- Adhesive applicator

- Splice plates with predrilled holes

- Flat strips and self-tapping screws for liner

Click here to read the Transmission & Distribution World magazine article featuring the COMPOSOLITE® Secondary Containment System.

Utility Trench Cover Systems

GEF's UTILICOVER® trench cover systems are strong and durable fiberglass covers which install easily and can be quickly removed by one person for trench access.

Features

Features

- Extremely lightweight

- Strong and durable

- Easy to install

- Safe

- Cost effective

- Available in custom widths

Case History

Two substation installation jobs in Virginia and Tennessee were recently completed, immediately displaying the benefits of the new covers. In the course of six and a half days, a three-man crew used only twelve tons of UTILICOVER® panels to replace seventy tons of concrete covers! The project manager stated the UTILICOVER® covers were installed more quickly by hand than the concrete covers could be removed with an excavator.

Non-Conductive Insulators

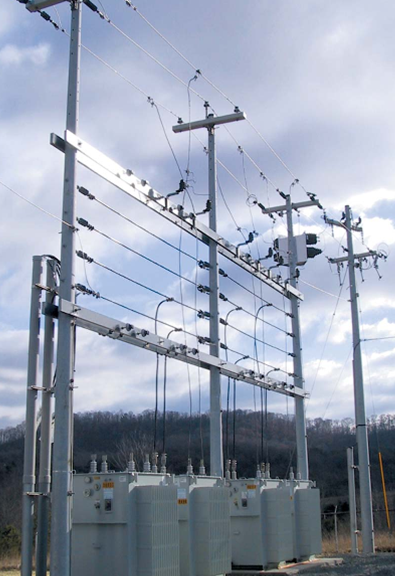

Fiberglass Cross-Arms for Substation

This municipal power provider is using 34' long EXTREN® rectangular tubing at a substation that generates electricity for the Johnson City Water Works Watuaga River Plant. The tubing replaces wooden cross-arms that supported electric wires that feed power to a group of transformers at the substation.

Fiberglass was chosen over steel for its non-conductive quality. The fiberglass tubes are lightweight, more durable, and quicker and easier to install than steel or wood. These tubes were so successful that they are now the standard throughout the system.

"If the arms go bad, the customer could be without power for six to seven hours so you want to use something that you know you won't have any problems with," one customer said. "The non-conductive feature of the fiberglass tubing also gave it a leg up over steel on this job."

Contact us for more information on these and other great fiberglass products. Already know what you need? Request For Quote